We would be happy to work with you to evaluate potential extensions to SETAGO® worker guidance with external devices.

Extension with external devices

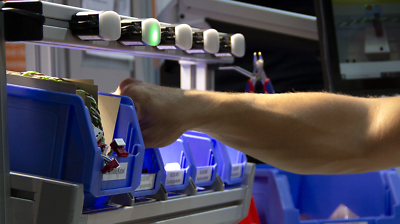

Expand SETAGO® worker guidance with external devices and components that increase productivity, enhance process safety or simplify the workflow! All devices can be connected with software and act actively in the work process! Of course, we will find a customised solution for your individual application if further devices need to be integrated. Whether screwdrivers, sensors or robotics, we will find a solution.