We would be happy to work with you to evaluate workstation solutions that will increase your productivity.

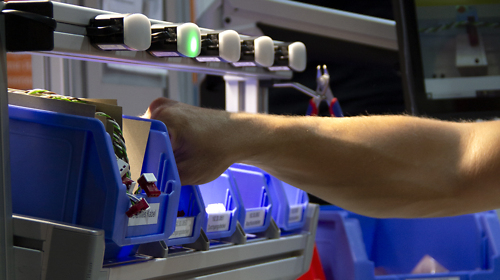

Higher productivity through individual LEAN workstations

Every product has its specifics when it comes to assembly. With the use of "standard" workstations an improvement in the assembly process can be achieved. However, our experience clearly shows that if you want to achieve maximum productivity and quality in the assembly process, you cannot avoid individual LEAN assembly workstations. The additional costs are usually amortized within a few months and our customers then benefit from massively higher productivity and quality. Benefit from our LEAN-live workshop, experience live within one day from which savings and advantages you can profit through an optimized workplace. Get in touch with our experts today.

Production errors or rejects are immediately identified

Height-adjustable workstations for the benefit of employees

ESD workstations for the protection of electronic components